|

|

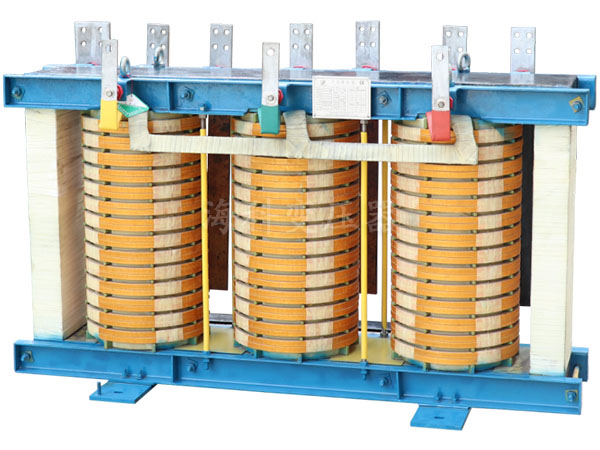

Phase number: single / three phase

Power range: 1-2000KVA

Rated voltage: 380V

Frequency: 50~60HZ

Impedance voltage: <4

Efficiency (η): 98%

Moisture proof: open

Core shape: step type

Winding form: layer winding

Cooling form: natural air cooling

Shape structure: vertical

Frequency characteristics: low frequency

Application range: rectification

Processing method: customized

Features

It is the original input current, and the secondary side outputs DC after rectifying the original. Airflow is a general term for three working modes of rectification, countercurrent and frequency conversion. Rectification is one of the most widely used. A transformer used as a power source for a rectifying device is called a rectifying transformer. Most of the industrial rectified DC power supplies are obtained by the AC grid through rectifier transformers and rectifier equipment.

Product Usage

Widely used in lighting, machine tools, mechanical and electronic equipment, medical equipment, rectifiers, etc. Product performance can meet the special requirements of users.

1. Electrochemical industry: This is the industry that uses the most rectifier transformers. It solves the non-ferrous metal compounds to produce aluminum, magnesium, copper and other metals; electrolyzes salt to make chlor-alkali; and electrolyzes water to produce hydrogen and oxygen.

2. DC power supply for traction: DC grid for mine or urban electric locomotives. Due to the overload of the valve side connector empty line, the line fault is more, the DC load changes greatly, and the motor car often starts, causing different degrees of short-term overload. For this reason, the temperature limit and current density of such transformers are lower, and the impedance is about 30% larger than the corresponding power transformer.

3. DC power supply for transmission: mainly used for power supply of DC motor in electric drive. Such as the armature and excitation of the rolling mill.

4. For DC transmission: The voltage of this type of rectifier transformer is generally above 110KV, and the capacity is tens of thousands of kilovolts.

Performance characteristics

1. Stable electrical performance: The product combines load characteristics and grid voltage fluctuations and atmospheric over-voltage conditions. According to the load condition of the rectifier transformer, a reasonable and reliable insulation level and insulation model are determined to ensure the electrical performance of the product is reliable and stable. Product environmental safety factor ≥ 1.67.

2. High degree of dynamic stability: The product winding has high mechanical strength and strong anti-burst ability to meet the extremely harsh load environment. In the design and manufacturing process, the source of dynamic instability caused by leakage flux of the transformer or abnormal transportation may be eliminated. The product has high dynamic stability. High resistance, 30% higher impedance than power transformers of the same capacity to suppress di/dt and effectively protect the rectifier components.

3, good thermal stability: advanced product design, strict control of the product's heating parts and the hottest temperature rise, and leave a sufficient temperature rise margin.

4. Strong overload capability: The product has strong overload capacity and over-voltage capability. It can operate safely for a long time under rated load conditions. It can operate at full load for a long time under 110% over-voltage condition (ambient temperature 40°C).

5, superior performance indicators: no-load current design, manufacturing value is lower than the national standard value of the same capacity S9 series transformers, full user economic and reliability.

|

Rated Capacity (KVA) |

Load loss (W) |

Load loss (W) |

No-load current (%) |

Short circuit impedance (%) |

Weight (kg) |

Overall size length * width * height (mm) |

| HK-30 | 350 | 930 | 1.4 | 4-5 | 300 | 420*160*640 |

| HK-50 | 430 | 1260 | 1.3 | 4-5 | 370 | 440*180*670 |

| HK-63 | 510 | 1500 | 1.3 | 4-5 | 440 | 480*210*730 |

| HK-80 | 550 | 1830 | 1.2 | 4-5 | 520 | 520*240*790 |

| HK-100 | 610 | 2120 | 1.0 | 4-5 | 610 | 570*280*860 |

| HK-125 | 720 | 2470 | 1.0 | 4-5 | 720 | 630*320*930 |

| HK-160 | 840 | 2880 | 0.9 | 4-5 | 870 | 690*360*1000 |

| HK-200 | 980 | 3390 | 0.9 | 4-5 | 1020 | 750*400*1080 |

| HK-250 | 1140 | 4000 | 0.8 | 4-5 | 1200 | 810*440*1160 |

| HK-315 | 1320 | 4720 | 0.8 | 4-5 | 1430 | 880*480*1240 |

| HK-400 | 1560 | 5690 | 0.8 | 4-5 | 1700 | 950*530*1330 |

| HK-500 | 1800 | 6900 | 0.6 | 4-5 | 2010 | 1020*580*1420 |

| HK-630 | 2100 | 8170 | 0.6 | 6-8 | 2385 | 1100*630*1520 |

| HK-800 | 2440 | 12000 | 0.6 | 6-8 | 2850 | 1190*680*1650 |

| HK-1000 | 2850 | 13500 | 0.6 | 6-8 | 3365 | 1280*730*1750 |

| HK-1250 | 3420 | 15600 | 0.5 | 6-8 | 3975 | 1370*790*1990 |

| HK-1600 | 3760 | 19500 | 0.5 | 6-8 | 4780 | 1480*860*1990 |

| HK-1800 | 3885 | 19100 | 0.5 | 6-8 | 5200 | 1590*930*2120 |

| HK-2000 | 4360 | 21000 | 0.5 | 6-8 | 5600 | 1730*1000*2300 |

Mobile website

Mobile website No public

No public