Product description

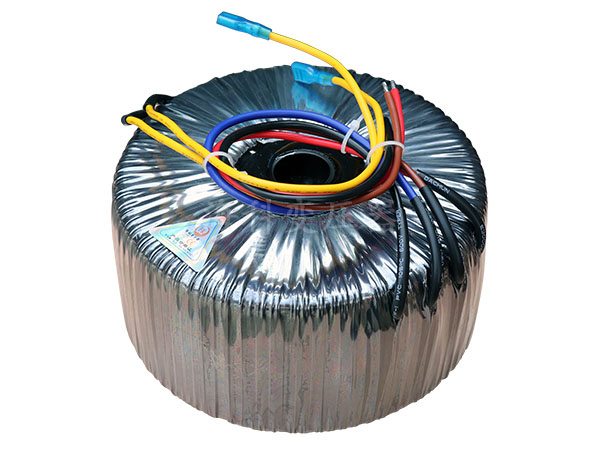

The toroidal transformer core is formed by high-quality high-grade oriented silicon steel coil with low power consumption. The coil of the toroidal transformer is evenly wound around the core. The direction of the magnetic flux generated by the coil is almost completely coincident with the magnetic circuit of the core, and the no-load loss is small and the volume is small. Small, low temperature rise, low noise, small magnetic leakage, simple structure and low price.

Product function

1. It is widely used in household electrical appliances and other electronic equipment with high technical requirements. Its main purpose is as a power transformer and an isolation transformer. The toroidal transformer has a complete series in foreign countries and is widely used in computers, medical equipment, telecommunications, instruments and lighting. In the past ten years, China's toroidal transformers have grown from scratch, and have formed a considerable scale of production so far. In addition to meeting domestic demand, a large number of exports have also been made. Domestically, it is mainly used in audio equipment and automatic control equipment for home appliances, as well as quartz lighting. The toroidal transformer is a competitive electronic transformer because of its excellent performance and price ratio, good output characteristics and anti-interference ability.

2, the electric efficiency is high, the iron core has no air gap, and the stacking factor can be as high as 95% or more.

3. The vibration noise is small. The iron core has no air gap to reduce the noise of the core induction vibration. The winding evenly surrounds the toroidal core, effectively reducing the “click” caused by magnetostriction. The operating temperature is low because the iron loss can be 1.1W/kg, the iron loss is small, the core temperature rises low, and the winding heats up well on the lower temperature core, so the transformer temperature rise is low.

4. It is easy to install. The toroidal transformer has only one mounting screw in the center, which is especially easy to install and disassemble in electronic equipment.

Features

The main advantage of the toroidal transformer is that the radiation field is low and the efficiency is high. In the case of halving the size and weight, the given capacity can be achieved. If a transformer with a slightly larger capacity is used, the temperature of the transformer can be lowered. The hole fixing method makes the ring type pressure change data easy to mount on the printed circuit board. The toroidal transformer has a high degree of flexibility to design the size of the transformer according to the requirements of the chassis and the overall assembly. Since the toroidal transformer is not required to manufacture a toroidal transformer, and the coil skeleton injection mold is not required, the production cycle is short, and it is suitable for small and medium batch production, and can meet the needs of continuous modification of contemporary electronic equipment.

Technical Parameters

| Capacity |

Height(mm) |

Outer diameter(mm) |

Weight(kg) |

Adjustment rate(%) |

Mounting bolt |

| HK-50W |

35 |

82 |

0.85 |

12 |

M6 |

| HK-100W |

45 |

93 |

1.5 |

8 |

M8 |

| HK-150W |

47 |

103 |

1.9 |

8 |

M8 |

| HK-200W |

53 |

115 |

2.4 |

8 |

M8 |

| HK-250W |

60 |

120 |

2.8 |

5 |

M8 |

| HK-300W |

60 |

125 |

3.4 |

5 |

M8 |

| HK-350W |

62 |

130 |

3.7 |

5 |

M8 |

| HK-400W |

65 |

135 |

3.95 |

5 |

M8 |

| HK-450W |

65 |

138 |

4.2 |

5 |

M8 |

| HK-500W |

68 |

140 |

4.9 |

5 |

M8 |

| HK-1000W |

74 |

183 |

8.3 |

4.5 |

M8 |

| HK-1500W |

78 |

200 |

11.5 |

4.5 |

M8 |

| HK-2000W |

88 |

225 |

15.2 |

4.5 |

M10 |

| HK-2500W |

110 |

195 |

17.5 |

4 |

M10 |

| HK-3000W |

115 |

205 |

18.8 |

4 |

M10 |

| HK-3500W |

115 |

210 |

19.2 |

4 |

M10 |

| HK-4000W |

120 |

215 |

19.8 |

4 |

M10 |

| HK-4500W |

120 |

220 |

20.5 |

4 |

M10 |

| HK-5000W |

126 |

225 |

22.5 |

4 |

M10 |

Mobile website

Mobile website No public

No public