|

|

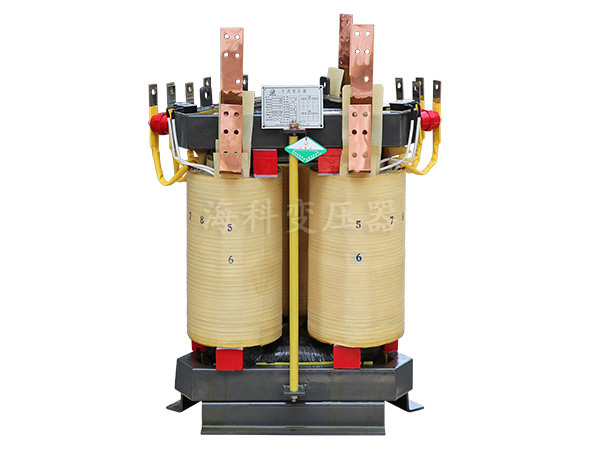

The three-dimensional coil core transformer breaks through the traditional planar structure, adopts a three-dimensional triangular structure, and makes the arrangement of the iron cores more rationally combined, and is formed by combining three identical single frames. The three-phase magnetic circuit is completely symmetric and equal in length, ensuring the balance of the three-phase power supply, and the magnetic resistance is greatly reduced, and the excitation current and the no-load loss are significantly reduced. It has higher mechanical strength and more stable structure.

Product structure characteristics

(1) Iron core

The key part of the three-dimensional coil core transformer is a three-dimensional winding core. The whole core is made up of three identical single frames, which are arranged in an equilateral triangle. Each frame consists of A plurality of trapezoidal strips are continuously wound in sequence, and the cross-section of the single frame is nearly semi-circular after winding, and the cross-section after the splitting is a quasi-polygon which is very close to a full circle. The whole magnetic circuit is tightly wound and has no air gap. The high magnetic direction and the magnetic path direction of the silicon steel strip are completely consistent, the magnetic resistance is small, and the three-phase magnetic circuit has the same length, thereby balancing the three phases, reducing the third harmonic of the transformer, and the like. Materials improve performance, reduce losses, reduce no-load current and reduce operating noise.

(2) Coil

The low-voltage winding is made of double-layered cylinder or foil, and the three-dimensional triangular low-voltage outlet is balanced. The high-voltage winding adopts a continuous structure, and the contact surface of the high-voltage coil and the air is large, and the heat dissipation and ventilation performance is good.

Performance parameter table

| Model | Rated Capacity(KVA) | Rated voltage | Connection group Label | Load loss(w) | Load loss 120℃(w) | No-load current(%) | Short circuit impedance(%) | Noise level sound pressure level(dB) | ||

| High pressure(KV) | Tap range | Low pressure(KV) | ||||||||

| HKSG10-30/10 | 30 | 6 6.3 6.6 10 10.5 11 |

±5% ±2*2.5% |

0.4 | Dyn11 or Yyn0 | 190 | 760 | 0.9 | 4.0 | 50 |

| HKSG10-50/10 | 50 | 270 | 1070 | 0.9 | 50 | |||||

| HKSG10-80/10 | 80 | 370 | 1480 | 0.9 | 50 | |||||

| HKSG10-100/10 | 100 | 400 | 1690 | 0.6 | 50 | |||||

| HKSG10-125/10 | 125 | 470 | 1980 | 0.6 | 50 | |||||

| HKSG10-160/10 | 160 | 540 | 2280 | 0.6 | 50 | |||||

| HKSG10-200/10 | 200 | 620 | 2710 | 0.5 | 50 | |||||

| HKSG10-250/10 | 250 | 720 | 2960 | 0.5 | 50 | |||||

| HKSG10-315/10 | 315 | 880 | 3720 | 0.5 | 50 | |||||

| HKSG10-400/10 | 400 | 980 | 4280 | 0.4 | 50 | |||||

| HKSG10-500/10 | 500 | 1160 | 5230 | 0.4 | 50 | |||||

| HKSG10-530/10 | 630 | 1340 | 6290 | 0.3 | 55 | |||||

| HKSG10-630/10 | 630 | 1300 | 6400 | 0.3 | 6.0 | 55 | ||||

| HKSG10-800/10 | 800 | 1520 | 7460 | 0.3 | 55 | |||||

| HKSG10-1000/10 | 1000 | 1770 | 8760 | 0.3 | 55 | |||||

| HKSG10-1250/10 | 1250 | 2090 | 10300 | 0.25 | 55 | |||||

| HKSG10-1600/10 | 1600 | 2450 | 12500 | 0.25 | 55 | |||||

| HKSG10-2000/10 | 2000 | 3050 | 15500 | 0.2 | 55 | |||||

| HKSG10-2500/10 | 2500 | 3600 | 18400 | 0.2 | 55 | |||||

Mobile website

Mobile website No public

No public