Characteristics of LED light source products

1. Cold light source, no heat radiation, suitable for bonding thermal sensitive materials.

2. That is to open the machine, without preheating, the irradiation intensity can reach more than 8000mW/cm squared

3. Small size makes it easy to integrate equipment into fully automatic production lines and equipment

4. UV LED no infrared radiation, no toxic gas production, in line with ROHS standards. Safer and more environmentally friendly than traditional mercury lamps

5. The service life is up to 20,000 hours, which can greatly reduce the operation cost and maintenance time

6. The connecting wire is bendable cable, which can be installed at will in the movable part to meet the needs of repeated movement

Advantages of LED light source products

1. Cold light source, no heat radiation, low temperature rise on the surface of the illuminated article, to solve the long-term thermal damage problems in optical communication and liquid crystal production, especially suitable for liquid crystal edge sealing, film printing and

other occasions requiring a small temperature rise. Low calorific value, can solve the problem of high calorific value of mercury lamp inkjet equipment. And led-uv light source is a high-purity single-band ultraviolet light, almost no infrared output, it is a cold light source

the workpiece will not be deformed by heat.

2. High efficiency: the light energy of led-uv is highly concentrated in a certain ultraviolet spectrum with effective curing effect, and the actual use effect is the same as that of the traditional high-pressure mercury lamp UV source with the light intensity of 1000mw /cm ^ 2

thus shortening the curing time. Traditional mercury lamp UV light brightness seem very high, but the heat is very high, because its spectrum is very wide, real effective curing effect of ultraviolet spectrum segment accounts for only part of the energy, a considerable part

of the visible light (mixed light) and ir (that generates heat), to the operator's eyes badly damaged and easy to make machining workpiece heat deformation.

3. Long service life: the service life of led-uv lamp is more than 10 times that of traditional mercury lamp, and the service life is not affected by switching times

4. Instant switch, can reach the maximum power ultraviolet output without preheating, and can restart immediately after closing

5. High energy, stable light output, good uniform irradiation effect, improve production efficiency

6. Customizable effective exposure area from 20mm to 2000mm in length

7. It contains no mercury and produces no ozone, making it a safer and greener alternative to traditional light sources

8. Low energy consumption, power consumption is only 10% of the traditional mercury lamp curing machine, can save 90% of electricity

9. The maintenance cost is almost zero, and the use of uv-led curing equipment will save at least 10,000 yuan/unit of consumables per year

10. Because the ultraviolet radiation device and related equipment are very compact, the need for the previous large mechanical installation space and pipeline construction, easy to set up. It can be said that led-uv curing system further enhances the environmental harmony

of traditional UV curing system. Led-uv technology is an upgrade of the original UV technology.

LED light source application field

1. Electronic field, such as optical, mobile phone, touch screen, hard disk, encoder, etc

2. Printing field, universal flat printing, offset coating machine screen printing machine, pad printing machine optical laser wheel rolling

3. Handicraft field, such as crystal, glass and other transparent products such as bonding

4. Medical field, injection needle and other adhesive

5. Decoration field: floor paint curing, aluminum ceiling curing, artificial marble surface curing

6. Metal surface paint solidification, furniture paint solidification, glass surface solidification

7. PCB blaster, etcher blaster, etc

8. UV coating of special-shaped products: UV coating equipment for the surface of stone, artificial stone, ceramic tile and helmet, pen holder and bottle surface curing equipment, UV coating equipment for jewelry box, pen container and audio surface, metal surface

rolling coating equipment;

9. UV coating equipment for electronic products: optical fiber point light UV curing machine, portable UV curing machine, liquid crystal UV curing machine,UV bonding curing machine, small desktop UV curing machine,UV curing oven, test box

10. Leather surface UV coating equipment: leather surface UV elastic varnish curing machine, leather whole UV glazing machine, sole UV irradiation machine

11. Plastics and electronics: dust purification, mobile phone toys, electrical housing UV coating machine, PCB UV curing machine, photosensitive line oil uniform rolling coating machine

12. Printing supporting UV equipment: wrinkle machine, ice flower machine, snow machine, printing packaging supporting UV glazing machine, UV curing machine, water-cooled UV curing system, Heidelberg Roland small sen jingdezhen offset printing plus UV

curing project, printing iron pot plus Install UV curing system

13. UV coating equipment: NC and PU paint surface coating machine curtain line, cabinet doors, stairs, wooden doors, wood lines, UV coating production line, floor surface UV coating production line, flat furniture NC, PU or UV roller coating primer and finish

equipment primer fill roller coating equipment, curtain washer, five and six side UV curing machine

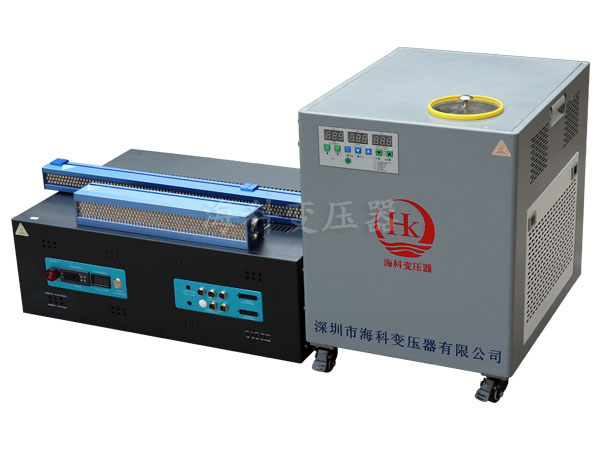

Technical Parameters

|

Size

|

Luminous width

|

Luminous surface length

|

The intensity of radiation

|

The peak wavelength

|

The Angle

|

Heat dissipation method

|

Remarks

|

|

25*50Nmm

|

15MM

|

50mm*N

|

8W/12W/15W/20W/25W

|

360/365/370/380/385

/395/405/410/420nm

Can be single or mixed

Single wavelength

or Mixture

|

30/60/90/120

|

Water-cooling

|

|

|

25MM

|

50mm*N

|

|

25MM

|

40mm*N

|

|

25MM

|

32.5mm*N

|

|

20MM

|

50mm*N

|

|

25MM

|

50mm*N

|

Mobile website

Mobile website No public

No public